Gas turbines are used in many industries and in many technologies. They are very efficient and are used in places that need propulsion. However, we will now in this article concentrate on marine gas turbine engines. As the name itself suggests the marine gas turbines are mostly used in sea and ships. They are basically used to propel a craft. The gas turbines are also found commonly in planes. This is because they are compact and they have a simple design. The advantages of using a gas turbine in planes are many. Marine gas turbine engines were used in shipping industries much later as compared to the aviation industry. This is mainly because when it comes to ships the disadvantages of a gas turbine has always been more than its advantages. We will discuss all about the marine gas turbine engine and how it evolved in this article.

About Marine Gas Turbine Engines

The common disadvantages of a marine gas turbine are that they consume a lot of fuel as a result the cost of operating the ship increases to a great extent. Looking at the cost that is incurred due to the use of a marine gas turbine the shipping companies have always tried to avoid them. However, the fact cannot be denied that marine gas turbines increase the speed of a boat or a ship by a huge factor. This is exactly why navy and military ships have always been using the marine gas turbine engines.

Of course of late there has been a sudden revolution in the use of the marine gas turbines. The technology has been developed so well that the marine gas turbines are now being used in merchant ships too. The low cost of fuel in some parts of the world has also been a major factor in the use of the marine gas turbines. From the late eighties the use of the marine gas turbines has increased all across the globe. The shipping companies have accepted the various advantages of a marine gas turbine and have openly accepted it as a part of the ship machinery.

How Marine Gas Turbine Engines Work?

We will now discuss a little on how exactly a marine gas turbine actually works. This turbine has a wheel that absorbs kinetic energy from the fluid stream. By fluids we mean water, air as well as steam. The turbines actually look like a windmill. The marine gas turbine can look like a wheel. The most complex turbines are used in aeroplanes. They are also called turbo fans because of their appearance. For example take a kids balloon and a pin wheel. Now blow in air to the balloon. Hold the balloon in front of the pin wheel you will notice how the air from the compressed balloon moves the pin wheel.

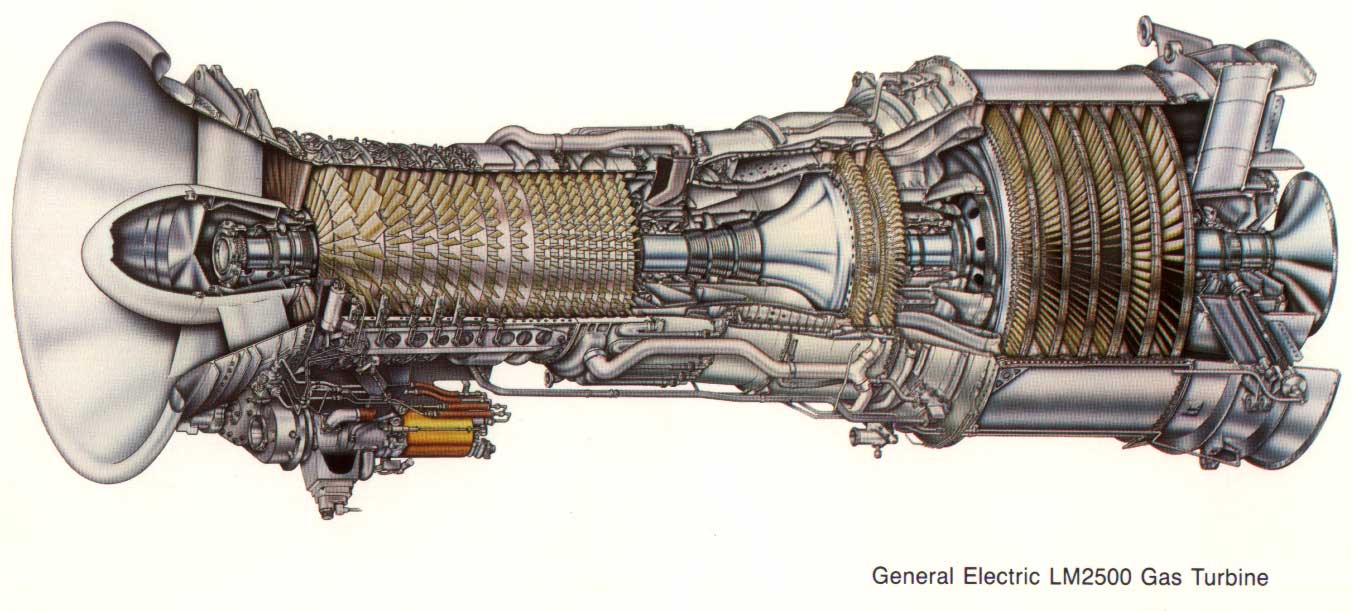

The marine gas turbine has three parts and they are compressor to compress the air into high pressure, a combustion area that is primarily used to burn the fuel and produce high pressure and the last part is the turbine that extracts energy from the high pressure in the compressor and the high velocity gas that flows in to the combustion chamber. In some cases the marine gas turbine engines have an accessory drive gear box that is used to drive the various pumps.

Sometimes a reduction gearbox is also provided to reduce the high revolutions of the turbine and make them of a more efficient speed for the propeller to manage. The compressor is so powerful that it can raise the pressure of the air by five to twenty times. The power to drive is derived from the turbine that is usually mounted on the shaft. The hot air in the combustion area ignites the injected fuel.

The fuel is usually very clean. It is petroleum oil that has a low viscosity. For the marine gas turbine engine to work properly the air and fuel ratio must be 60:1 by weight. This ignites and produces a high pressure gas. This gas can be at times contaminated by the products that are created during the combustion process. The temperature of the gas may vary from eight hundred to about eleven hundred Celsius. This is how the thermal energy is converted into kinetic energy in a marine gas turbine. The result of it is the high velocity steam that moves the blade of the turbine.

The functioning if a marine gas turbine is relatively simple. The marine gas turbine relies on oil completely for lubrication of its various parts. The marine gas turbine requires regular maintenance. The marine gas turbine is so hot that synthetic oils are mostly used for lubricating the marine gas turbine. The fuel delivery system must also be checked regularly as it does the most vital function of delivering fuel uniformly to all parts of the marine gas turbine.

As we know that the sea water is extremely salty. This is exactly why a lot of salt may accumulate inside the marine gas turbine. This is exactly why the marine gas turbine must be maintained properly so that less of corrosion occurs. There can be more challenge in maintenance of the marine gas turbine. This is exactly why they are designed in such a way that there is less dampening to the structures inside the marine gas turbine.

With technology it has been made possible that less fuel is consumed in this whole process. This is exactly why more and more ships across the world are opting for the marine gas turbine. Well as technology has simplified it has also complicated the marine gas turbine. In some marine gas turbine two series of marine gas turbine are used. You must be wondering why we need a two series marine gas turbine. Well the reason is that when there is a two series then the first series provide the driver for the compressor. The second turbine on the other hand is used to propel. This division of work ensures that there is a better torque and as a result the ship is propelled better.

We hope by reading this article you have got a good idea of what marine gas turbine are all about and how we can ensure that the marine gas turbine are maintained and properly used. There are many companies across the world that makes marine gas turbine. They are Rolls Royce, GE, Solar, etc. Nowadays marine gas turbine are also used in speedboats and small motor boats.

Marine Gas Turbine Engines,