These directions are based on the assumption that engine works fine and has no maintenance problems and it is getting started after a long gap or a major overhaul so just follow these steps..

> Preliminaries before starting up the engine after extant periods out of service or after overhauls

> Check levels of liquids in all taking belonging to the engine. Replenish all cooling system and vent them

> Switch on all cooling-water and lubricating oil pumps. Check the flow of the cooling media where possible. Check all components connected to the lubricating oil system for correct oil flow.

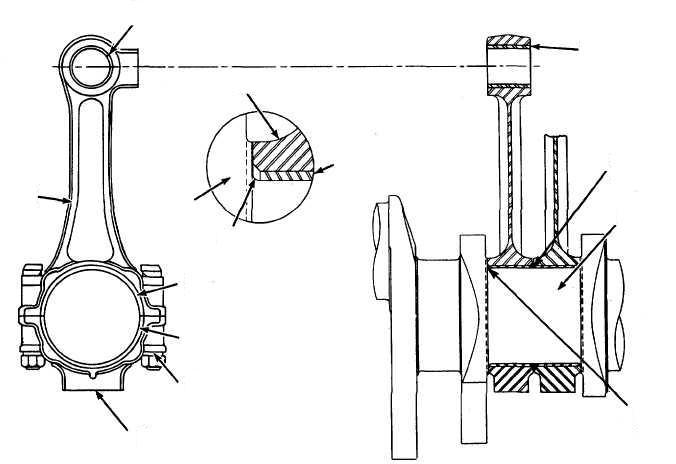

> Turn the engine by means of the turning gear and with the indicator cocks open to ascertain that nothing obstructs the movement of the running gear. At the same time operate the hand cracks of the cylinder lubricators so as to ensure satisfactory lubrication of the cylinders from the very beginning. Note whether the hand cracks can be operated without applying any abnormal force

> Start up fuel-booster pump. Prime fuel system

> Check pressure in the starting air bottles and drain off any water

> Check the functions of the reversing servomotor, the regulating linkage, and the blocking device for reversing gear as well as fuel level for emergency running (without governor)

> The air side of the air cooler and the space underneath the piston undersides are to be drained by opening the appropriate drain cocks

> Drain condensation from pressure-reducing station

To be observed if engine has been stopped for same time, apart from idle periods during manoeuvring

1. Turn the engine with the indicator cocks open

2. Disengage the turning gear and secure it

3. Check the oil and the water pressures

4. If the engine is to be started on fuel of high viscosity the fuel must be pre-heated to the required temperature. Bring fuel injector cooling water to the prescribed service temperature

5. Open starting air shut-off valve and check whether the automatic starting air stop valve is set to “automatic”

6. Set the hand switch off the auxiliary blower to position “Automatic”

Starting steps

- Speed setting lever, move to start position

- Push starting button

- As soon as the engine turns over, (ignition) release starting button and check pressures on engine and the speed of turbocharger(S)

- Adjust the signaled manoeuvring speed with the aid of the speed-setting lever

- Full speed ahead (Telegraph position)

- Open the vent cock on the starting air distribution pipe

- Increase the speed slowly until service speed is reached. The full load positions of the load indicator must not be overridden

- Adjust water and oil temperature

- Carry out regular checks and re-adjust pressures and temperatures if necessary

- Check pressure drop of charge air through turbocharger air filter and air cooler

- Check the behavior of the engine by comparing the instrument readings with figures given in the trial report, taking into account the engine and the engine load.

Important readings:

– Load indicator position

– Turbocharger speed

– Scavenge-air pressure and exhaust temperature before turbo-charger

Higher engine room temperatures and higher temperature after air cooler, result in higher exhaust temperatures. The maximum values should not be exceeded.

- Check combustion by observing the colour of the exhaust gases

- Check the correct cylinder lubricating oil consumption

- Leave the vents in the uppermost points of cooling water spaces constantly open (cylinder covers, turbocharger and charge-air cooler)

- Check the levels of all water and oil tanks, as well as the collecting tanks of the leakage pipes

- Check cooling water systems of cylinders, pistons and fuel injectors for contamination

- Check the stuffing boxes of the piston cooling pipes and the stand pipes for abnormal leakages

- Open the starting air main stuff off valve. Check if the automatic starting air stop valve is in position “Automatic”

- Set hand switch of auxiliary blower to position “Automatic”

- Move the speed setting lever to the start-position. In principle, this is to be effected before each start and therefore also before each maneuvers. When reversing the engine while it us still turning the previous direction of rotation, the selected starting position should be somewhat higher than when starting the engine from a stand still.

- Move the telegraph to the new required position. Thereby the fuel leakage is pulled to position “0” by the cut out servomotor, and, at the same time, the reversing servomotor moves to the new position.

- As soon as the reversing servomotor is in its correct end position, the engine can be started, even though it may still be turned over in the old running direction by the propeller. In this case the starting push button must be pushed somewhat longer in position starting in order to give the engine sufficient speed in the new running direction