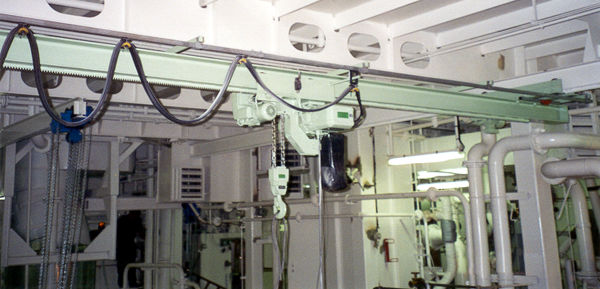

Cranes are used on ships both inside the engine room as well as on the deck (for certain types of ships) mainly for lifting heavy loads. Overhead cranes are found in most ships. In this article we will discuss eight tips to buy an overhead crane.

Agreeably, the decision to buy a crane is not made by marine engineers and deck officers but it is the construction and design aspect, still it would be useful to know what all parameters are looked at during installation of overhead cranes.

Overhead cranes are used for movement of all types of materials in all types of environments, even apart from ships. Whether you are buying a crane for the first time or replacing an existing one, take the time to review the services it is expected to perform and the exact purpose for which it will operate. A detailed understanding of the service requirements is essential to ensure a long life, safe and economical operation. In this article we’ll cover 8 tips for buying an overhead crane.

1. Operator controls

One of the first and simplest decision to make is often overlooked until the buyer is far along in the process, and that is, will the crane be operated remotely or from and operators cab ? This simple decision will eliminate a number of options and simplify your task going forward.

2. CMAA Service Classifications

The Service Class assigned to a crane takes into account the loads it will lift, the frequency, and it’s duty cycle. A crane that must lift 65% of its rated load once an hour is built quit differently than a crane lifting 40% of it rated load 20 times an hour. Having a clear understanding of the range of loads and frequency of use will save you money and allow you to plan properly for maintenance.

3. Make a list of the services you require of the crane.

Consider the maximum loads, the average load, and estimate the number of loads to be lifted each hour and each shift. Estimate the number of shifts per day and the number of days per week. Estimate the typical distance a load most travel and how fast. Then use that information to select the Service Classification you think you’ll require.

- Class A Infrequent Service – Precise handling of equipment at low speeds. Long idle periods between use.

- Class B Light Service – Variable loads from no load to full rated loads with only 2 to 5 lifts per hour at distances averaging 10 ft.

- Class C Moderate Service – Average loads of 50% rated capacity with 5 to 1 lifts per hour over average distances of 15 ft. Number of lifts that exceed rated capacity are less than 50%.

- Class D Heavy Duty – Average loads at 50% capacity with 10-20 lifts per hour with an average distance of 15ft. With no more than 65% at the rated capacity.

- Class E Severe Service – Loads frequently approaching rate capacity with 20 or more lifts each hour.

- Class F Continuous Severe – Continuous operation at rated capacity in severe conditions.

4. Types of cranes

Obviously the type of crane must be considered. There are several to choose from including jib cranes, work station cranes, under running and top running cranes, gantry cranes, and girder cranes. The important point to note is that very few manufacturers specialize in all types of cranes. So selecting the type of crane first, will reduce the number of manufacturers you need approach saving you time.

5. Types of hoists

Most often the type of hoist chosen is dictated by the manufacturers crane design. This can reduce the field of manufacturers further. In general there are three types of hoists, electric chain or cable hoists, pneumatic hosts, and manual hoists. This is a fairly easy selection. Pneumatic hoists can handle loads between 125kg to 100 tons. Aside from their superior load rating, a pneumatic hoist is often chosen for environments which are hostile to electric motors, or for which electric current could be dangerous. Electric chain hoists can handle loads up to 5 tons, while electric cable hoists can handle loads up to 100 tons.

6. Electrical components

This again requires a clear understanding of your service requirements. Overloading the motor and braking system will greatly shorten the life of the components, reduce safety, and add to operating costs. Make sure the supplier is properly matching the motor and braking system to your needs. You might also consider an enclosed frame design. It will help dissipate more heat from the motor and protect it from the environment extending it’s life.

7. Motor controls

Motor control technology has come a long way in recent decades. Variable frequency drives provide superior crane positioning and control of speeds. But you should take into account the operating environment, not all are suitable for solid state controls. Discuss the life-cycle and costs for service on control systems.

8. Special process cranes

There are some applications that require special designs, such as nuclear powered ships. There are very few suppliers and manufactures that can delivery such equipment. Don’t waste time soliciting bids from unqualified suppliers. Ask up front if they experience delivering products with your specifications. If not, move on to the next supplier.

Below-the-hook attachments

Don’t forget to consider the actual lifting attachments. What are you lifting, loose materials or liquids, bundles, or coils? The crane supplier can recommend attachments, but there are companies that specialize in below-the-hook accessories that will offer you insight that would be useful early on in the purchasing processing.

Buying and installing a crane on the ship takes a good deal of preparation. The concerned personnel should take into account the above factors before going for a particular set of crane.

Eight Tips for Buying an Overhead Crane ,